DOWSIL™ 991 Silicone High-Performance Sealant is a one-part, neutral-cure silicone sealant designed for a wide range of applications where a long-lasting and durable seal is required. It is a highly flexible and versatile sealant that can bond to various substrates, including glass, aluminum, steel, ceramics, and many plastics.

When exposed to atmospheric moisture, it cures to a flexible elastomer, resulting in a long-lasting, weather-resistant seal capable of forming strong bonds with most building materials. It provides excellent weatherproofing performance in dynamically moving building joints due to its medium modulus and good adhesion.

Features & Benefits

The features and benefits of DOWSIL™ 991 Silicone High-Performance Sealant include:

- Versatility: The sealant is suitable for bonding a wide range of substrates including glass, metal, and plastic.

- Excellent Adhesion: The sealant has excellent adhesion to many substrates, including difficult-to-bond materials.

- Durability: The sealant provides a long-lasting seal that is resistant to weathering, aging, and UV radiation.

- Flexibility: The sealant is highly flexible, making it ideal for applications where movement or vibration is expected.

- Non-sagging: The sealant is non-sagging, which means that it will not drip or slump during the application, allowing for precise placement.

- Easy to Apply: The sealant is a one-part product, which means that it does not require mixing or special handling. It can be applied with standard caulking guns or other dispensing equipment.

- Temperature Resistance: The sealant can withstand a wide range of temperatures, from -60°C to 204°C (-76°F to 400°F), making it suitable for use in extreme environments.

- Chemical Resistance: The sealant is resistant to many chemicals and solvents, making it suitable for use in harsh chemical environments.

Applications

DOWSIL™ 991 Silicone High Performance Sealant is a versatile product that can be used in a variety of applications. Some of the most common applications of this sealant include:

- Industrial and commercial construction: It can be used to seal and bond materials in construction projects, such as concrete, masonry, metal, and glass. It is commonly used for sealing expansion joints, curtain walls, windows, and doors.

- Automotive and aerospace: The sealant can be used for sealing and bonding materials in automotive and aerospace applications, including sealing windshields and windows, bonding panels, and sealing engine components.

- Electrical and electronic: It is an excellent choice for electrical and electronic applications due to its excellent dielectric properties. It can be used for sealing and bonding electronic components, as well as for potting and encapsulating.

- Marine and underwater: The sealant is suitable for use in marine and underwater applications, as it is resistant to saltwater and UV radiation. It can be used for sealing and bonding materials in boats and other marine structures.

- HVAC and plumbing: The sealant can be used in HVAC and plumbing applications, including sealing and bonding pipes, ductwork, and fittings.

Colors

DOWSILTM 991 Silicone High Performance Sealant comes in nine different colors, including black, grey, bronze, limestone, white, charcoal, dark grey, sandstone, and pink.

Weatherseal Joint Design

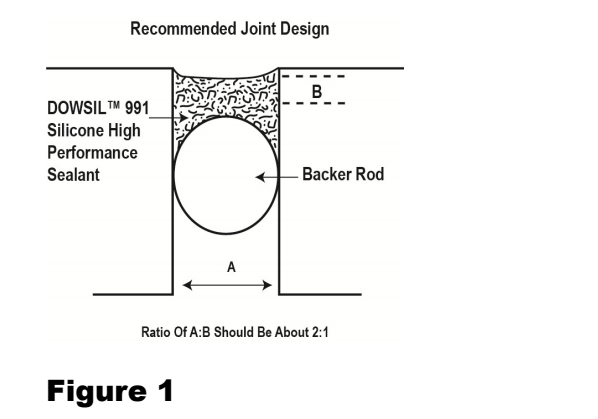

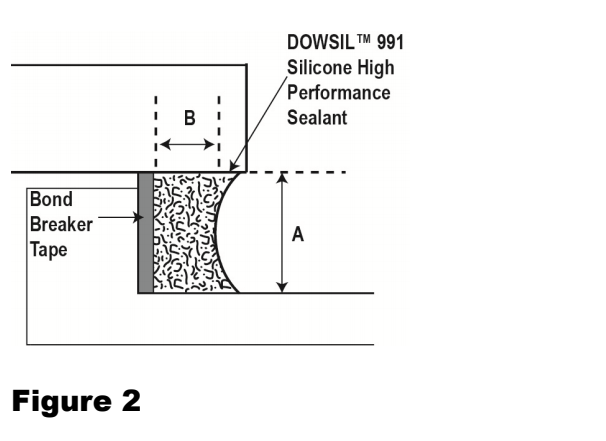

A thin silicone bead will allow for more movement than a thick bead (see Figure 1). For joints where excessive movement is expected, DOWSILTM 991 Silicone High-Performance Sealant should be no thicker than 12 mm and no thinner than 6 mm. The ideal joint width-to-sealant depth ratio is about 2:1.

Most joints should be backed with open-cell polyurethane foam, closed-cell polyethylene, or non-gassing polyolefin; use polyethylene tape for joints that are too shallow to allow backer rods (see Figure 2). These materials allow for the use of a thin bead and act as bond breakers, allowing the silicone sealant to move freely with the joint.

The width of building expansion joints varies due to seasonal and daily temperature changes. If DOWSILTM 991 Silicone High-Performance Sealant cannot be installed when the design width is halfway between the dimensional extremes, the designed joint should be at least twice as wide as the total anticipated joint movement. Joint design should be four times the anticipated movement due to construction tolerances and material variations, according to good architectural practice.

Applicable Standards

Some of the applicable standards for DOWSIL™ 991 Silicone High Performance Sealant are:

- ASTM C920: Standard Specification for Elastomeric Joint Sealants. This standard specifies the physical properties, test methods, and requirements for elastomeric joint sealants used in building construction.

- Federal Specification TT-S-00230C: Type II, Class A: This specification covers the requirements for a one-component silicone sealant for use in sealing expansion and control joints in concrete.

- Federal Specification TT-S-001543A: Type F: This specification covers the requirements for a one-component silicone sealant for use in sealing interior and exterior joints in building construction.

Usable Life and Storage

The usable life of the sealant can be affected by factors such as temperature, humidity, and exposure to air. In general, higher temperatures and humidity can reduce the usable life of the sealant, while lower temperatures and humidity can extend it.

Limitations

Some of the limitations of DOWSIL™ 991 Silicone High-Performance Sealant are:

- Not paintable: It is not designed to be painted. If the sealant needs to be painted, it is recommended to use a compatible primer and paint system.

- Not suitable for structural glazing: It is not suitable for use in structural glazing applications. For these types of applications, a two-part silicone structural glazing sealant is recommended.

- Not recommended for submerged or continuous water immersion applications: DOWSIL™ 991 Silicone High-Performance Sealant is not recommended for use in applications where the sealant will be continuously immersed in water, such as swimming pools or aquariums.

- Not recommended for contact with certain materials: It is not recommended for contact with certain materials, such as natural rubber, EPDM rubber, or some plastics, without proper compatibility testing.

- Not recommended for use in high-temperature applications: It is not recommended for use in applications where the sealant will be exposed to continuous high temperatures above 204°C (400°F).