Typical Product Data

| Chemical base | 1-C silicone |

| Cure mechanism | Moisture-curing |

| Density (uncured) (CQP 006-4) | 1.5 kg/l |

| Non-sag properties (CQP 061-4 / ISO 7390) | ≤ 2mm |

| Application temperature | 5 °C - 40 °C |

| Skin time3(CQP 019-2) | 20 min. |

| Elastic recovery(GB/T 14683) | 90% |

| Elongation at break (CQP 036-1 / ISO 37) | 900 % |

| 100% modulus (CQP 555-1 / GB/T 14683) | 0.4 N/mm2 |

| Service temperature | -40°C - 150 °C |

Description

Sikasil® WS-305 S is a neutralcuring silicone sealant with a high movement capability and excellent adhesion to a wide range of substrates.

Product Benefits

- Meets requirements of GB/T14683-2017

- Outstanding UV and weathering resistance

- Adheres well to many substrates including glass, metals, coated and painted metals, plastics and wood

Areas of Application

Sikasil® WS-305 S can be used for weatherproofing and sealing applications where durability under severe conditions is required.

Sikasil® WS-305 S is particularly suited as a weather seal for curtain walling and windows.

This product is suitable for professional experienced users only. Tests with actual substrates and conditions have to be performed to ensure adhesion and material compatibility.

Cure Mechanism

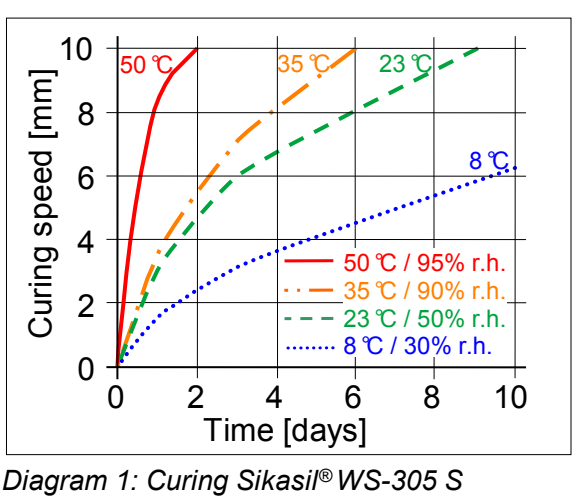

Sikasil® WS-305 S cures by reaction with atmospheric moisture. The reaction thus starts at the

surface and proceeds to the core of the joint. The curing speed depends on the relative humidity and the temperature (see diagram 1). Heating above 50 °C to speed-up the vulcanization is not advisable as it may lead to bubble formation.At low temperatures the water content of the air is lower and the curing reaction proceeds more slowly.

Method of Application

Surface preparation

Surfaces must be clean, dry and free from oil, grease and dust.

Advice on specific applications and surface pretreatment methods is available from the Technical

Department of Sika Industry.

Application

After suitable joint and substrate preparation, Sikasil® WS-305 S is gunned into place. Joints must be properly dimensioned as changes are no longer possible after construction. For optimum performance the joint width needs to be designed according to the movement capability of the sealant based on the actual expected movement. The minimum joint depth is 6 mm and a width / depth ratio of 2:1 must be respected. For backfilling it is recommended to use closed cell, sealant compatible

foam backer rods e.g. high resilience polyethylene foam rod. If joints are too shallow for backing material to be employed, we

recommend using a polyethylene tape. This acts as a release film (bond breaker), allowing the joint to move and the silicone to stretch freely.

For more information contact the Technical Department of Sika Industry.

Tooling and finishing

Tooling and finishing must be carried out within the skin time of the adhesive.

When tooling freshly applied

Sikasil® WS-305 S press the adhesive to the joint flanks to get a good wetting of the bonding surface.

Removal

Uncured Sikasil® WS-305 S may be removed from tools and equipment with Sika® Remover208 or another suitable solvent.

Once cured, the material can only be removed mechanically.

Hands and exposed skin should be washed immediately using Sika®

Handclean towels or a suitable industrial hand cleaner and water.

Do not use solvents!

Overpainting

Sikasil® WS-305 S cannot be overpainted.

Packaging Information

Unipack 600 ml

Description

Sikasil® WS-305 S is a neutralcuring silicone sealant with a high movement capability and excellent adhesion to a wide range of substrates.

Product Benefits

- Meets requirements of GB/T14683-2017

- Outstanding UV and weathering resistance

- Adheres well to many substrates including glass, metals, coated and painted metals, plastics and wood